24hr Media Things To Know Before You Get This

24hr Media Things To Know Before You Get This

Blog Article

What Does 24hr Media Mean?

Table of ContentsWhat Does 24hr Media Do?24hr Media Fundamentals Explained24hr Media Can Be Fun For EveryoneThe smart Trick of 24hr Media That Nobody is Talking AboutThe Definitive Guide for 24hr Media

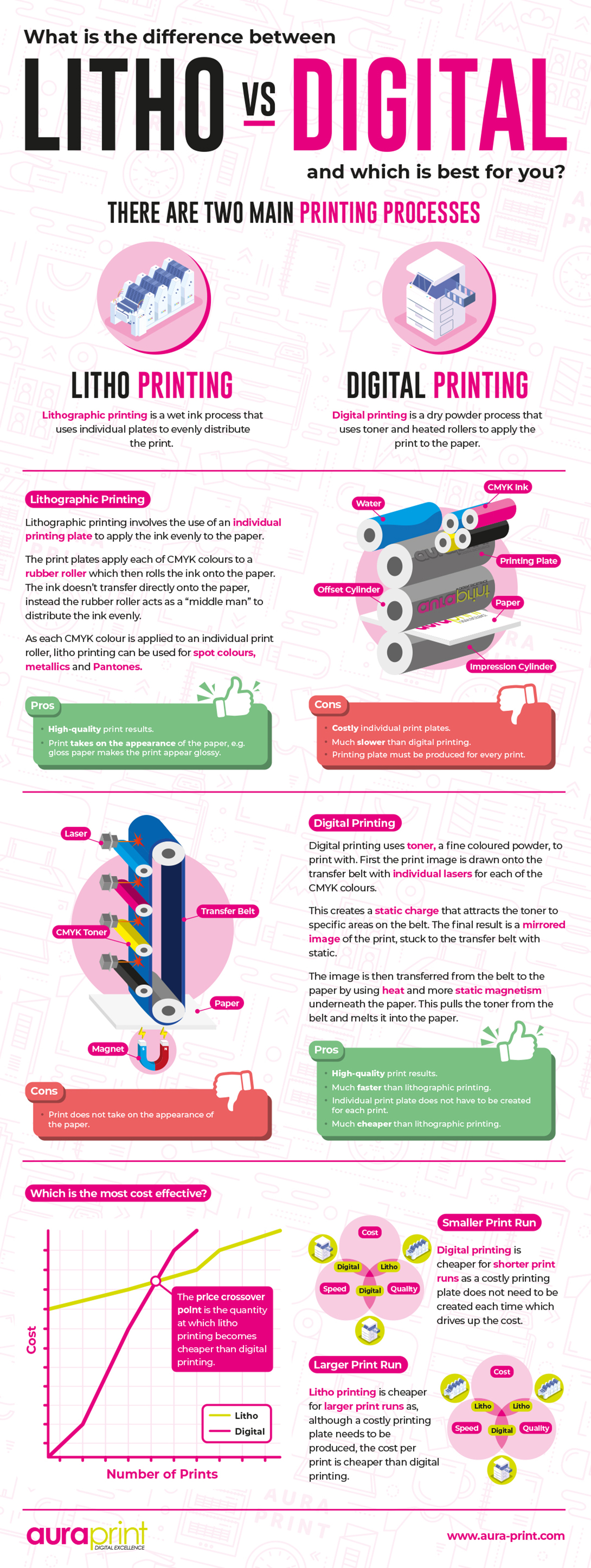

Improvements in print technology are transforming the interactions playing area when it comes to quality, affordability and innovative capabilities. Countered printing and digital printing are the significant processes by which print work are embarked on both making use of four-color printing techniques. Each choice has its advantages, supplying different methods to meet the demands of varied manufacturing tasks.

Generally, this has actually been one of the most consistent strategy for exactly preserving color suits, making it excellent for print runs that only call for fixed printing such as pre-printed kinds, brochures, flyers, organization cards, and bulk postcard mailings. Due to the fixed nature of litho printing, it is not excellent for variable print pieces that will be mailed to private receivers such as statements, letters, and individualized postcards.

Some Known Facts About 24hr Media.

The most up to date advancements in print innovation are helping to bring much of countered's advantages right into the digital printing globe absolutely changing the face of modern printing! There are some crucial differences in between Offset Printing and Digital Printing (Large Format Printing). This guide shows the benefits and drawbacks of each printing approach. There is an undeniable and growing variety of benefits to using the electronic print procedure.

Today's digital print devices is amongst the most advanced on the marketplace. Here are a few of the most significant advantages of utilizing electronic printing: dominate the electronic print space, with full-color printing finished in one process and effortlessly printed straight from a print documents. Without an extensive set-up process, the calibration time of a certain task is shortened, adding to quicker print time and overall shipment.

The inkjet printing procedure has actually assisted to reinvent the sector along with the quality and rate of the result. The most recent inkjet innovation can publish on traditional countered stocks with dull, silk, and shiny coatings. High-grade digital print coupled with software-managed color monitoring methods adds optimum worth to publish items and makes manufacturing processes more reliable than countered.

Some Known Details About 24hr Media

(https://za24media.carrd.co/)

Precise amounts of ink and printer toner are used to prevent waste. Environmentally friendly and eco-friendly inks and printer toners are also offered for even more lasting printing. Digital print also removes the demand to clean plates or blankets with unsafe chemicals at the end of the printing process. As the quality of electronic print solutions increases, the benefits come to be progressively apparent and valuable.

Variable information assists organizations reach their specific customers and target market with uniquely-created and individualized content. As modern technology boosts, the high read review quality of digital printing has become second-to-none, with greater detail, color match abilities and total precision. Without the need to wash plates or make use of excess ink, digital printing is additionally less inefficient and generally extra eco-friendly.

Typical printing methods, such as offset lithography ("countered") and flexography ("flexo"), involve several make-ready actions to transfer an initial picture to a substrate. These approaches need the manufacturing of a collection of plates placed on a cylinder to transfer ink that creates the preferred picture when integrated on paperboard and other product packaging materials. Signage.

8 Simple Techniques For 24hr Media

While electronic printing is a feasible choice for a lot of short-run print workunique occasions, prototyping, or various other considerationsits modern-day capabilities really display in rapid turn-arounds. Being able to tailor product packaging via variable data printing has opened new opportunities for you to engage with your clients in even more personalized ways. Digital printing, with fewer moving pieces, is more active than offset in this regard.

Minimized set-up time saves cash on the front end. And considering that these are not substantial mass orders, smaller sized companies can afford to print without having to meet the higher and a lot more costly print limits of traditional printing.

Make sure you team up with a printing and product packaging companion who has the ideal qualifications. While eleventh-hour printing and personalization are a massive benefit, digital may not constantly be the ideal approach for you. Counter printing has the advantage of cost-effectiveness with huge print runs, especially those with innovative decorative effects and specialized coatings.

24hr Media - Truths

Lithographic presses make use of two print platesa favorable and a negativeto transfer premium color graphics onto a suitable substrate. The favorable plate, with its smooth surface, attracts oil-based inks and drives away water. In contrast, the adverse plate, with its harsh appearance, soaks up water and fends off oil. Rubber rollers are then made use of to move the photo from home plate to the corrugated surface.

Corrugated paper can in some cases verify to be a difficult surface area to publish on, however Litho prints to a separate surface area and is after that laminated to it, making it simple to publish top quality pictures. It can be extremely consistent, also for long terms. Actually, the extra you publish, the less expensive the expenses come to be for Litho.

What Litho doesn't give you is exactly what Digital does, customization. Costly established up Longer turnaround No Variable Data Printing Smaller sized color gamut, colors can be less intense Digital printing is the process of printing electronic photos straight onto the corrugated substrate making use of a single-pass, direct-to-corrugate method.

Report this page